Guiding Principles

The principles we follow, and why.

Circular Economy Principles

PACT’s work is guided by the Circular Economy Principles. The idea of a circular economy is simple: to use resources for as long as possible, ideally – forever. We believe this will help eliminate plastic pollution and extend the lifespan of plastics beyond a single use.

That’s why our targets and work are based around the principles of the circular economy. Mouse over the diagram below to explore how it works.

Close the tap

First, we reduce production of virgin plastic and increase demand for sustainable sources of plastic or other materials — also known as closing the tap. Closing the tap also allows businesses to better handle resource risk management.

Close the loop

This is where we keep plastics in use for as long as possible, through innovation. This involves redesigning of products and packaging to optimise them for easier reuse and/or recycling. This also involves eliminating unnecessary plastic, such as cling wrap around a box.

From here, we can shift from a linear economy — where raw materials are turned into products, that get disposed of — to a circular one. Through redesigning, businesses have the opportunity to save on manufacturing costs in the long run.

Reuse

Part of closing the loop, we also promote reuse, where brands build customer relationships of a collaborative nature. Think of businesses and customers working together to reuse empty soap bottles or rent clothes instead of buying them.

By rewarding eco-conscious customers, brands can strengthen loyalty and encourage repeat business. This boosts innovation and creates a more competitive economy, as well as jobs. On a large scale, industrial symbiosis is possible - where businesses work together by using each other’s waste or byproducts for their own manufacturing. Ultimately, this brings businesses financial savings in the long run.

Maximum recovery of recyclable plastic

By improving our waste management facilities, we can maximise collection and recovery of recyclable plastic. Recyclable plastic is melted and remoulded to create recycled packaging, as a sustainable alternative.

Ultimate aim: Eliminate plastic pollution

Ultimately, we want to eliminate plastic pollution in nature by using circular economy principles.

Close the loop

This is where we keep plastics in use for as long as possible, through innovation. This involves redesigning of products and packaging to optimise them for easier reuse and/or recycling. This also involves eliminating unnecessary plastic, such as cling wrap around a box.

From here, we can shift from a linear economy — where raw materials are turned into products, that get disposed of — to a circular one. Through redesigning, businesses have the opportunity to save on manufacturing costs in the long run.

Close the tap

First, we reduce production of virgin plastic and increase demand for sustainable sources of plastic or other materials — also known as closing the tap. Closing the tap also allows businesses to better handle resource risk management.

Close the loop

This is where we keep plastics in use for as long as possible, through innovation. This involves redesigning of products and packaging to optimise them for easier reuse and/or recycling. This also involves eliminating unnecessary plastic, such as cling wrap around a box. From here, we can shift from a linear economy — where raw materials are turned into products, that get disposed of — to a circular one. Through redesigning, businesses have the opportunity to save on manufacturing costs in the long run.

Reuse

Part of closing the loop, we also promote reuse, where brands build customer relationships of a collaborative nature. Think of businesses and customers working together to reuse empty soap bottles or rent clothes instead of buying them.

By rewarding eco-conscious customers, brands can strengthen loyalty and encourage repeat business. This boosts innovation and creates a more competitive economy, as well as jobs. On a large scale, industrial symbiosis is possible - where businesses work together by using each other’s waste or byproducts for their own manufacturing. Ultimately, this brings businesses financial savings in the long run.

Maximum recovery of recyclable plastic

By improving our waste management facilities, we can maximise collection and recovery of recyclable plastic. Recyclable plastic is melted and remoulded to create recycled packaging, as a sustainable alternative.

Ultimate aim: Eliminate plastic pollution

Ultimately, we want to eliminate plastic pollution in nature by using circular economy principles.

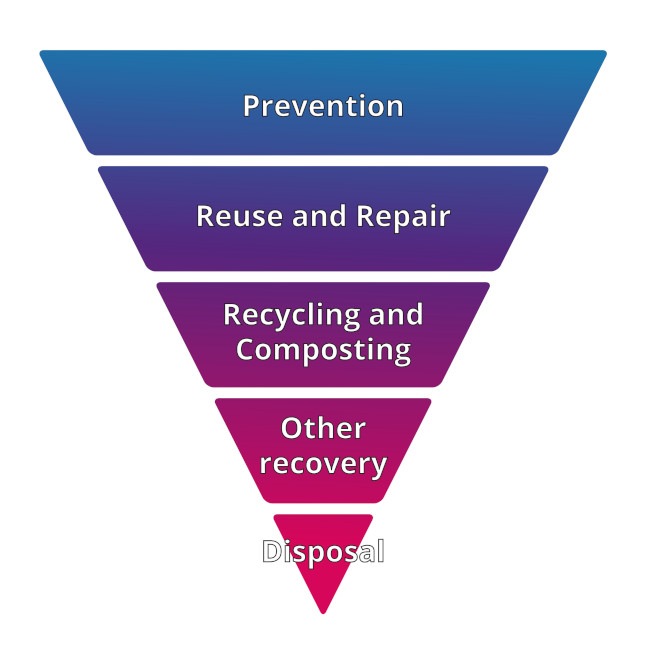

The General Waste Hierarchy

The waste management hierarchy provides guidelines on how waste should be handled. By following this hierarchy, it will enable maximum recovery of a material’s value.

Prevention – Prudent usage of material through innovative design and manufacturing, resulting in less wastage of valuable material.

Reuse and Repair – Checking, cleaning, repairing, and/or refurbishing whole items or spare parts, such that the product or materials can be used again. This extends the material lifespan through repeated use and repair, minimising the need for extraction of virgin material.

Recycling and Composting – Turning waste into a secondary material or product through the following ways:

- Upcycling – Waste is turned into a new product that has the equivalent or more value than the original product

- Downcycling – Waste is turned into a new product that has a lesser value than the original product

- Composting – The use of living organisms, such as bacteria and fungi, to process organic waste, in the presence of oxygen and under specific conditions (e.g. high humidity and temperatures). Compost, which can be used as a soil fertiliser, is formed as a secondary product.

- Industrial Composting: Composting that is carried out at an industrial site on a large scale.

- Industrial composting requires sustained high temperatures (55-60°C) combined with a high relative humidity and the presence of oxygen. Some sample conditions for a material to earn a “compostable” label based on EU standard (standards are dependent on countries) include:

- The packaging material and its relevant organic components (>1 wt.%) are naturally biodegradable;

- Disintegration of the packaging material takes place in a composting process for organic waste within a certain time (EU standard is 12 weeks);

- The packaging does not become harmful to the environment during the composting process

- Home Composting: Composting that can be carried out at home. Home compost piles are of a smaller size than industrial composter. Temperature required is much lower (around 45°C) and less constant compared to industrial composting conditions due to the smaller amount of compostable material. As a result of the lower temperature, far fewer materials are actually home-compostable and the degradation rate is generally much slower compared to industrial composting.

Other Recovery – recovery of other useful by-products (of a lower value) through the following processes:

- Anaerobic Digestion: A process that breaks down organic matter (primarily food waste) in the absence of oxygen. Biogas is the main byproduct. A small amount of bio-fertiliser is also produced.

- Incineration with energy recovery: Waste is incinerated at high temperatures, producing energy in the form of heat and electricity. This transforms waste into a fuel source.

Disposal – discarding of waste through the following methods:

- Incineration with no energy recovery: Waste is burned, forming ash. No energy is recovered in the process.

- Sanitary Landfill: A place where waste is sent to, where it remains in the environment for an immeasurable number of years. This is commonly found in other countries, not in Singapore.

- Open Burning: Uncontrolled burning in open land, presenting itself as high risk. There are few measures to control toxins emitting from the burning process, often leading to immense air pollution and health hazards.

- Unsanitary Landfill: A dumpsite with little control by authorities, presenting as high risk of water pollution, air pollution, landslips, scavengers, and detriment to human health.

Bio-plastics and Biodegradability

These are biodegradable materials that will degrade completely into substances found in nature. For example, there are materials that can be broken down by microorganisms (bacteria or fungi) into water, naturally occurring gases like carbon dioxide and methane and biomass (e.g. growth of the microorganism population). Biodegradability depends strongly on environmental conditions: temperature and the presence of microorganisms, oxygen and water.

WWF does not indiscriminately support all bio-based plastics, as the environmental advantages of these materials differ depending on the specific feedstock used and the subsequent product lifecycle.

- 1st generation bio-plastics are made from edible crops

- 2nd generation bio-plastics are made from inedible plants

- 3rd generation bio-plastics are made from biomass that does not require arable land (e.g. byproducts, waste streams, or high-tech landless production such as algae)

- 4th generation bio-plastics are made from biomass that does not require the destruction of raw materials to manufacture the plastics

The generation a feedstock belongs to is not necessarily indicative of its broader environmental sustainability. The generation is also no guarantee of climate impact, as there are several influencing factors including the plastic product’s lifetime and whether it is burnt at end-of-life. Thus, it is not possible to predict the effects that the cultivation of the feedstock will have on the local population or the environment. Bio-based plastic feedstocks must be evaluated case by case, on their advantages and trade-offs, including their region-specific impacts.

WWF believes that materials should not be designed to end up in nature. As part of a circular economy, materials should be designed with the intention to be recaptured and not littered into natural ecosystems. Biodegradable plastics can be valuable when coupled with proper infrastructure, but it is not a solution to litter or marine debris. WWF does not accept any solution where plastics, biodegradable or otherwise, are leaked into nature. WWF believes that compostable plastics may be appropriate for specific uses, but will only be advantageous if collection and processing is sufficient to recover the material.

Oxo-degradable additives

Oxo-degradable additives are substances added to conventional plastics to promote oxidation. Oxidation brittles and fragments the material in order to be digestible by microorganisms, but evidence shows that this desired effect is not achieved. There is no credible evidence that these additives result in positive outcomes for the environment. WWF does not support the use of oxo-degradable materials, as they do not result in better environmental outcomes and contribute to microplastic pollution.

Are you a business who wants to learn more about the PACT guiding principles?